ccLEAP Maintenance

Smart maintenance with digital support.

With intelligent maintenance, you ensure high equipment availability, safety, and reliable operation.

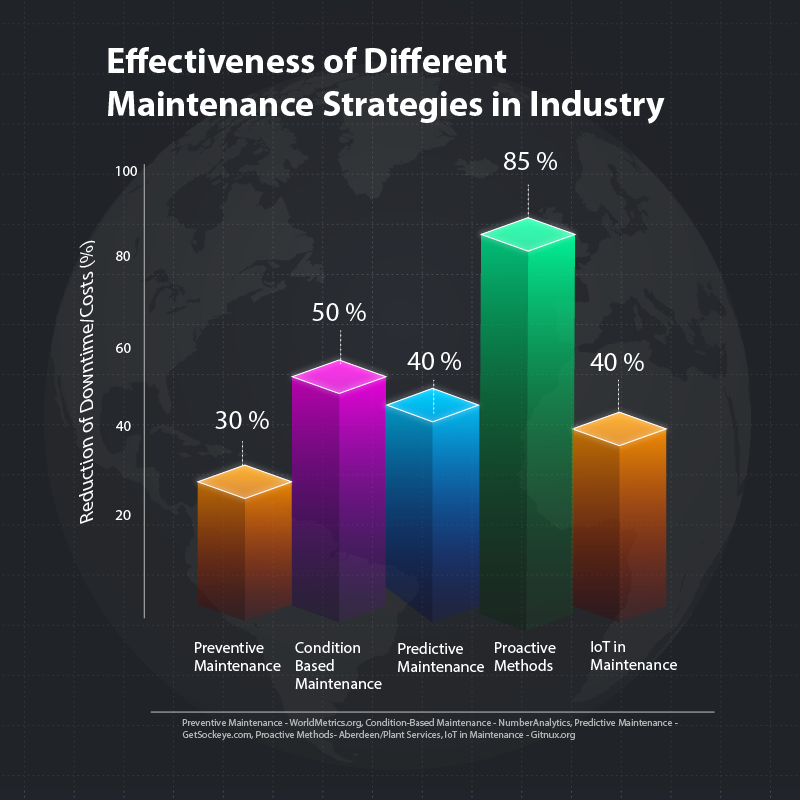

Benefits of digital maintenance

up to 30 %

Implementing digital maintenance—using data, sensors, and advanced analytics to detect faults early can reduce maintenance costs by up to 30%.

up to 30 %

Digital transformation through maintenance can cut machine downtime by up to 30%.

up to 40 %

Digitally transforming operational processes, including maintenance, can raise productivity by up to 40%.

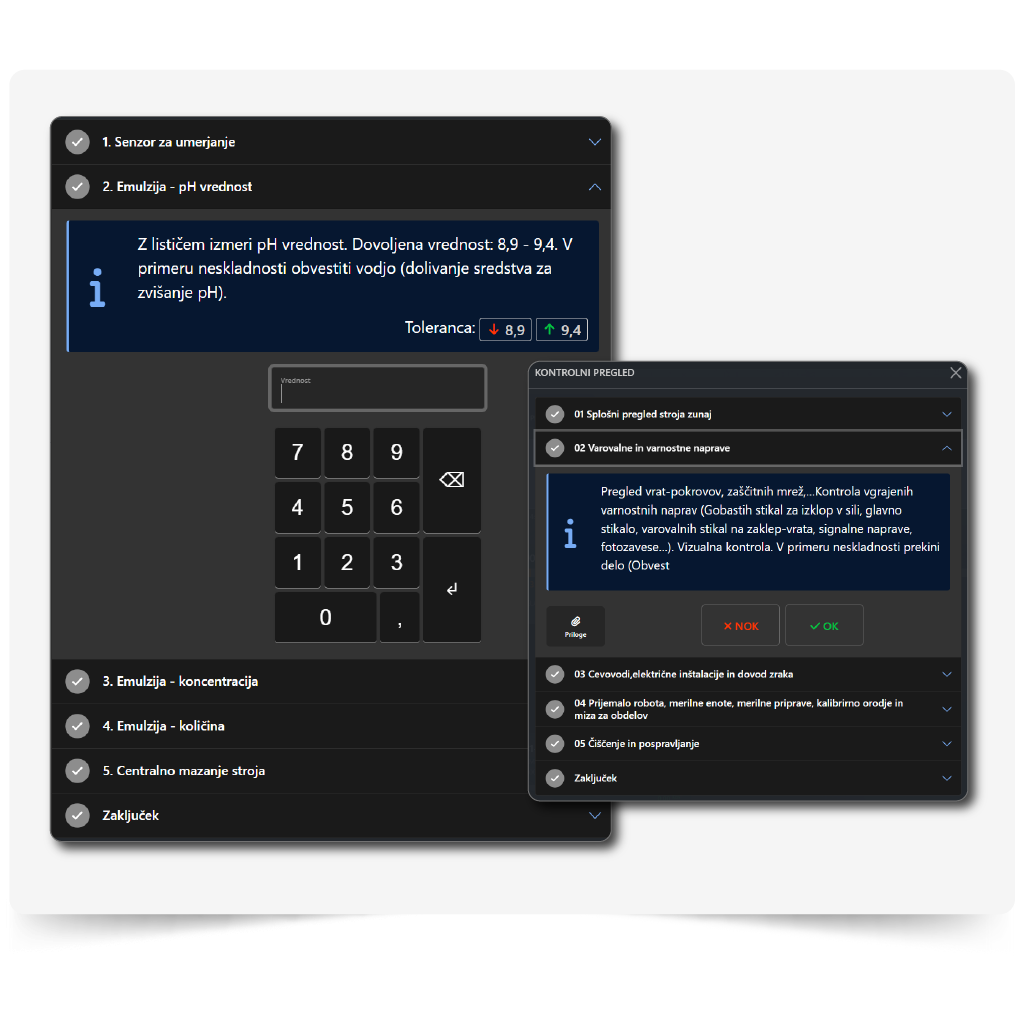

Digital first-level maintenance

-

Employee involvement in digital equipment monitoring

Digital inspection tools empower employees to easily and efficiently monitor machines, equipment, and processes. All data is automatically recorded, stored, and accessible in real time.

-

Ensuring a safe working environment

Systematic checks of critical machine components ensure safety elements are fully operational and the machine is safe to use.

-

Extended machine lifespan

Digitalized maintenance enhances monitoring of equipment condition, helping you detect wear, faults, and deviations early—resulting in a longer machine lifespan, fewer unexpected stoppages, and more reliable production.

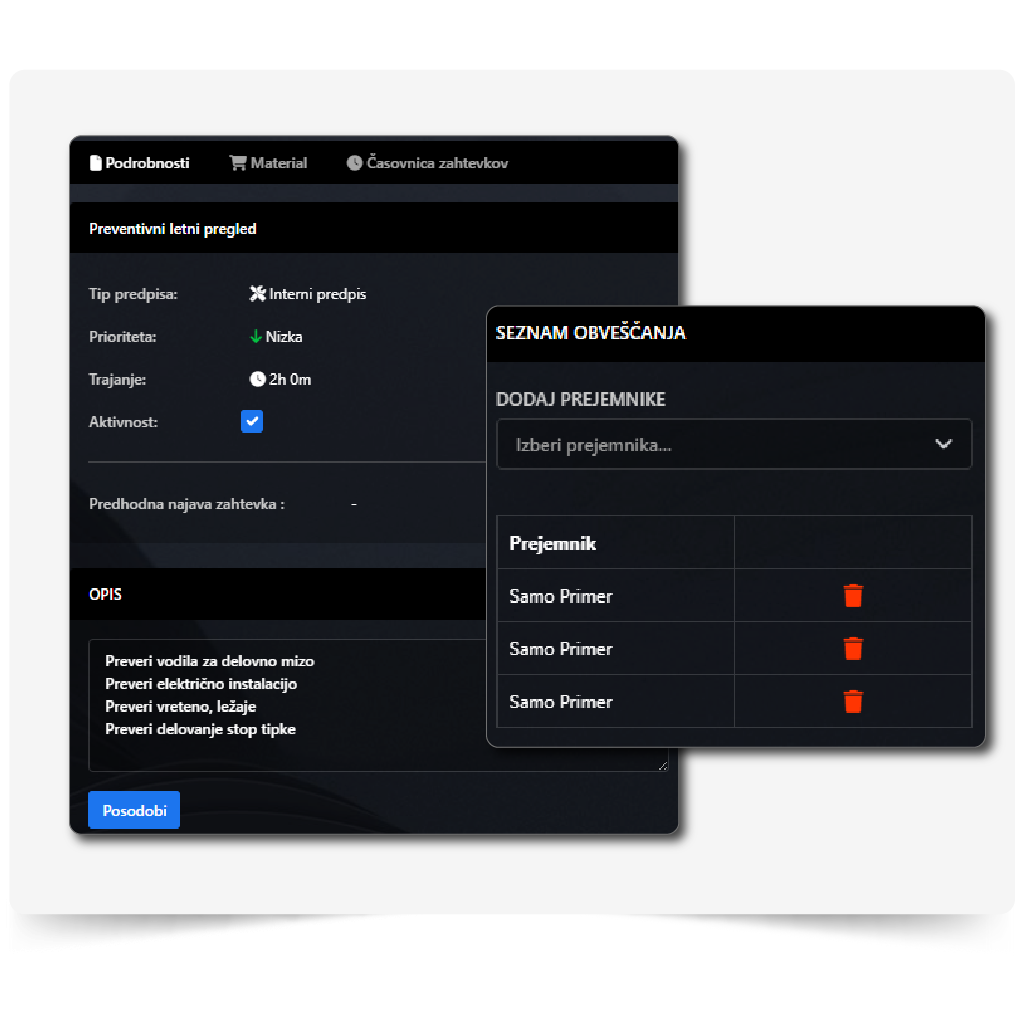

Preventive maintenance for smooth production

-

Easy scheduling of preventive inspections

Correctly determined intervals for preventive inspections are crucial for the long-term reliability and safety of production equipment. With the ccLEAP maintenance system, you can set intervals based on actual machine usage, loads, operating conditions, and past fault history.

-

Notification recipient lists

To ensure that preventive maintenance is carried out on time and without interruption, it is essential to effectively notify all parties involved. Our system allows you to easily set up notification recipient lists to ensure that no task is overlooked.

-

Checklist of required materials

For smooth and efficient preventive maintenance, it is essential that all necessary materials and tools are prepared in a timely manner. The ccLEAP system provides a simple and transparent list of supplies, ensuring that the maintenance team always has all the necessary components at their disposal.

-

Internal knowledge base

Reporting machine downtime or repairs is not just about solving the immediate problem—it also builds an internal knowledge base. Every record of the cause, solution, or special circumstances helps other employees, enables faster action in the future, and reduces the recurrence of errors.

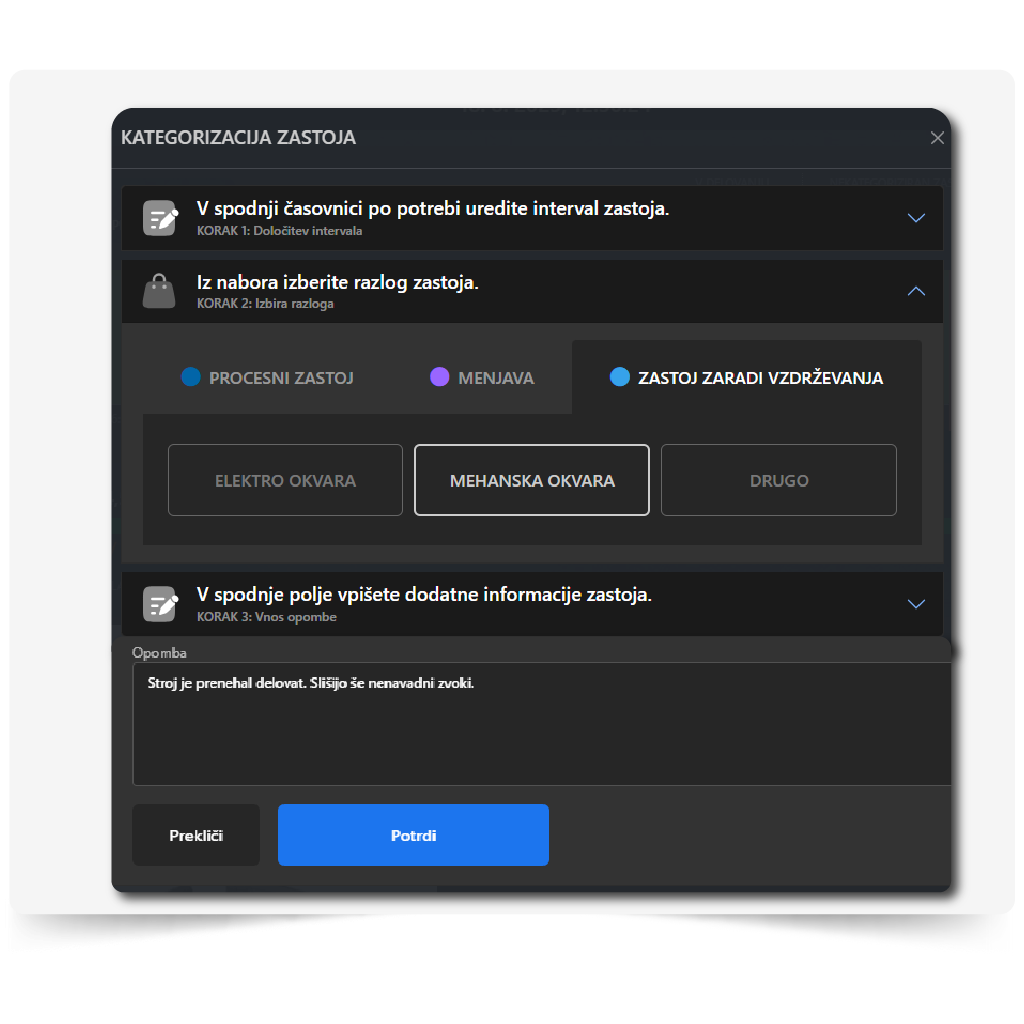

When it happens – act quickly and effectively

-

Incident alerting

The ccLEAP mobile app for downtime notifications enables maintenance teams to respond quickly, resolve issues, and prevent major consequences—loss of time, materials, or product quality.

-

Immediate reporting

For smooth production, it is important that employees report material consumption and completed work immediately after finishing their tasks. By entering data on an ongoing basis, they ensure accurate information, reduce the possibility of errors, and enable effective planning and better traceability throughout the entire process.

-

Maintenance record management

The ccLEAP system allows you to add images, text descriptions of problems and solutions, and relevant documentation for a comprehensive and transparent record of service work performed.

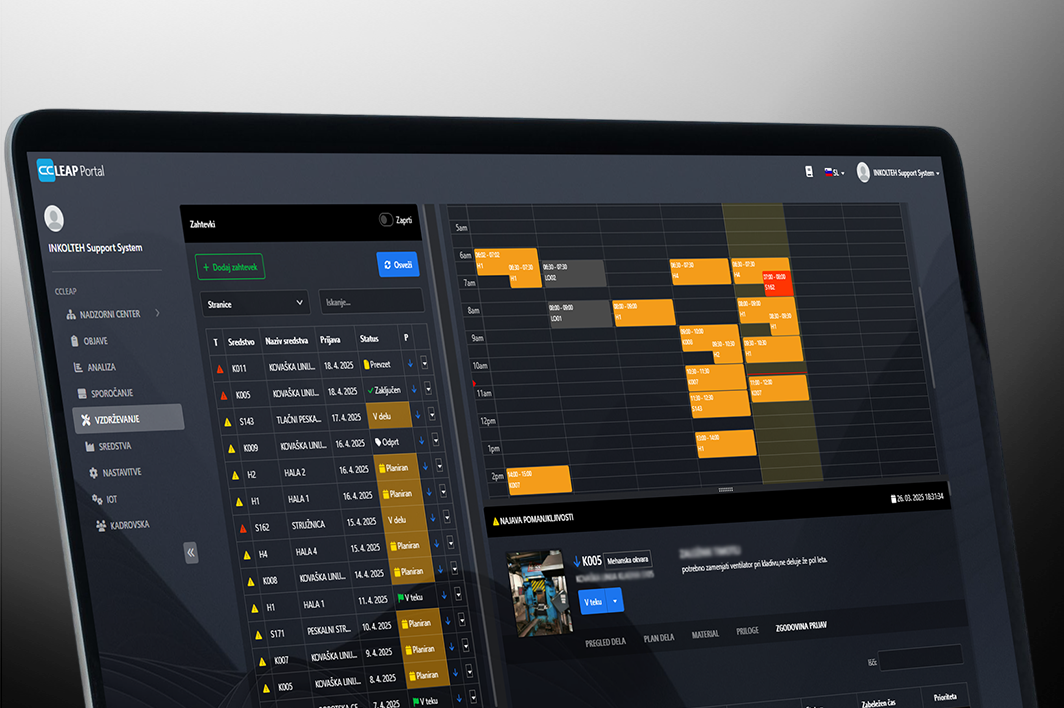

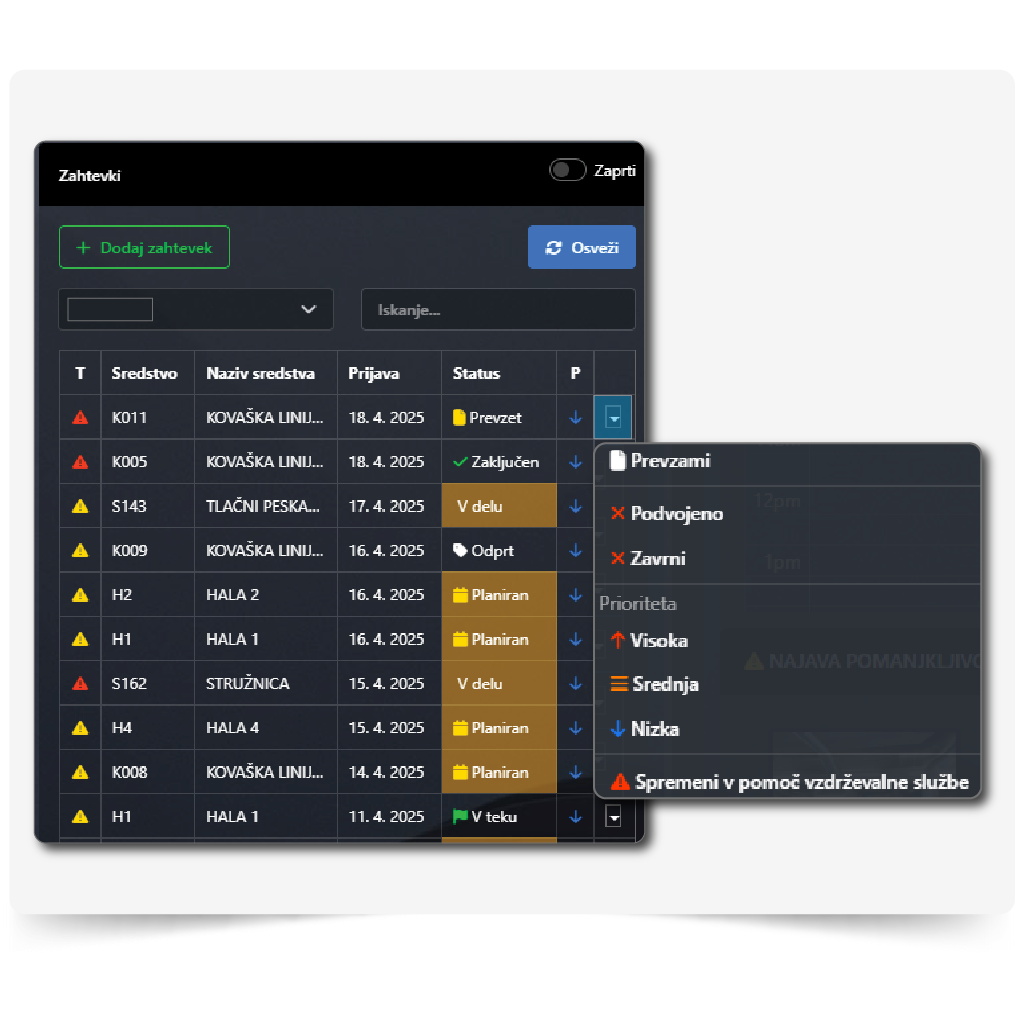

Comprehensive system for planning asset maintenance

-

Planning and reviewing maintenance requests

Overview of planned maintenance requests and their priorities. With a clear calendar and visual alerts, you can respond in a timely manner and ensure smooth production operations.

-

Digital service log - maintenance logbook

The service logbook is a digital record of all maintenance and service activities performed on your machines and equipment. It gives you a complete overview of past interventions, repairs, and regular inspections.

-

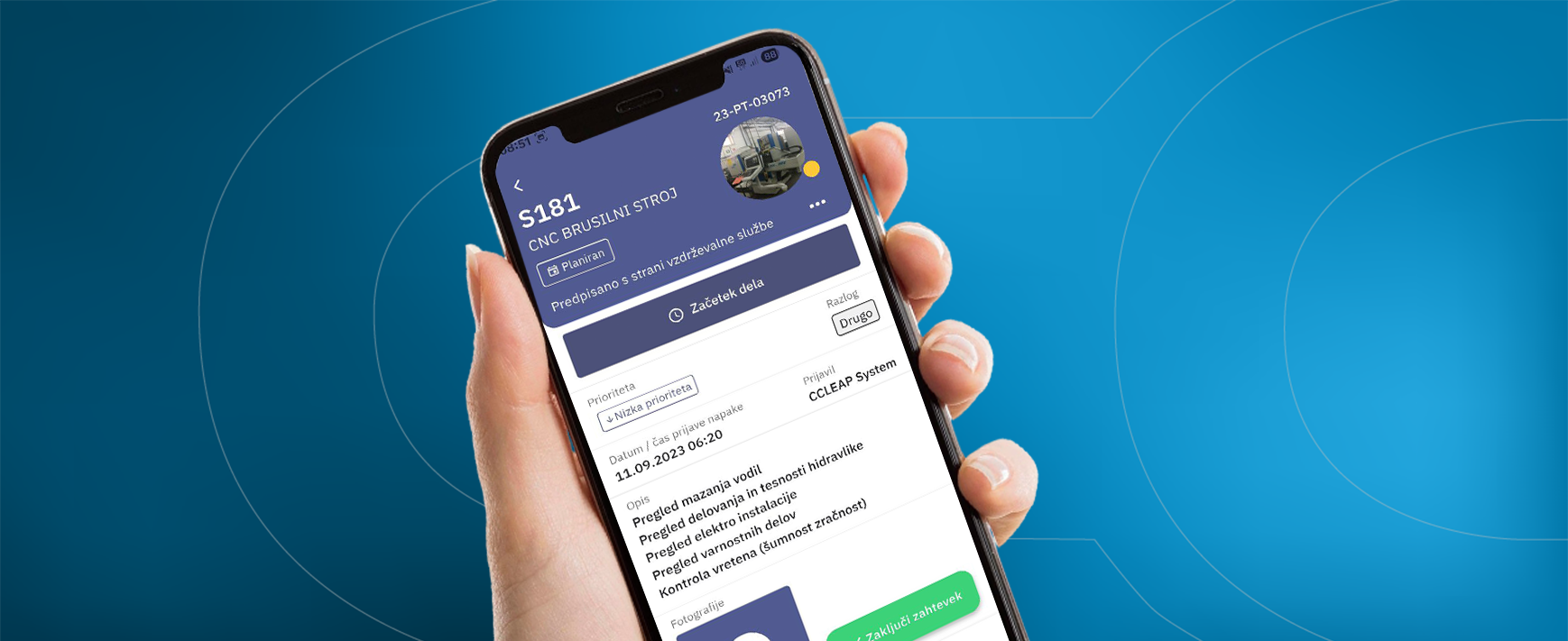

ccLEAP mobile app for maintenance teams

The ccLEAP mobile application for planning and managing maintenance of production assets enables quick and easy assignment of requests to maintenance personnel directly at the workplace, thereby improving efficiency and reducing downtime.

Maintenance at your fingertips

ccLEAP mobile app

for maintenance teams

Our mobile-friendly maintenance software enables maintenance teams to be more efficient in the field—with real-time updates, digital approvals, and smart task tracking.

- Planning and reviewing claims

- Real-time notifications

- Review of photographs and documentation

- Recording time spent

- Adding comments

- Maintenance list

Try ccLEAP Maintenance

Visit our free demo center and explore our self-maintenance services.