ccLEAP Displays

Modern solution for data display in manufacturing

With digital displays, you can deliver key information efficiently and reliably directly to the workplace.

Overview, planning and communication

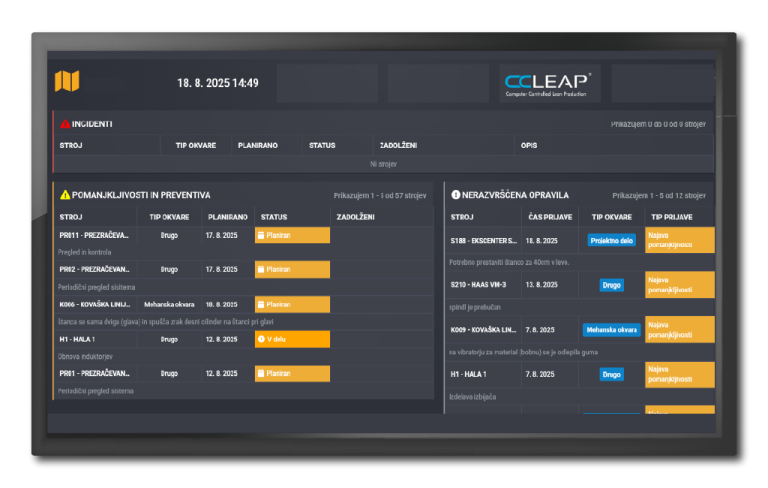

A planning board enables display of real-time data, giving immediate insight into the state of production and facilitating easier decision-making.

Increase employee awareness with clear visual alerts and messages, ensuring alignment across the whole team.

A fast and transparent flow of information in production to improve coordination among teams and enable immediate responses.

Easy way to share content

ccLEAP displays are user-friendly and highly adaptable. Besides standard graphical displays, they also allow the development of fully custom solutions tailored to the customer. This way you can show content exactly as your production or business process requires.

Choose among different ccLEAP Displays

A wide selection of displays allows you to adapt content according to different locations and employee needs.

A company sought to increase transparency and employee involvement in the production process, so they introduced digital displays that show key production metrics like OEE, plus other important operational data in real time. Previously these data were accessible only to management or arrived with delay; now they are visible to all employees in prominent locations on the production floor. This allows employees immediate insight into results, downtimes, and potential issues, encouraging greater accountability, faster action, and stronger motivation to reach production goals and continuous improvement.

To improve internal communication, a company installed digital displays in visible places in production where staff can monitor important announcements, changes in the work process, weather forecasts, clock, and other useful information in real time. Previously, information was often communicated with delay or verbally, causing confusion and mistakes. With the installation of displays, the flow of information has significantly improved; employees are always up to date, contributing to better team alignment, timeliness, awareness, and satisfaction.

At the customer’s production facility, workers used to spend up to 45 minutes every morning manually assigning operators to machines, which delayed production startup. Introducing a digital planning board, which enables automatic and clear scheduling based on staff availability and order status, reduced this process to less than 10 minutes. Workers now immediately see where to start at the beginning of their shift, enabling a faster start, greater efficiency, and better utilization of working time.

Digital displays for safety announcements, alarms, and reminders about mandatory use of personal protective equipment significantly improve the flow of key information in the workplace. Previously, employees were often informed with delay or via paper notices which were not always visible or up to date. Now important alerts are automatically shown in real time, directly where they are most needed. This increases awareness of safety measures, reduces the risk of workplace accidents, and strengthens the safety culture among employees.

By installing a digital board at the company entrance, company XYZ enabled a warm and personalized welcome for visitors, new employees, and business partners upon arrival. Previously such greetings were rare or prepared manually; now the board automatically displays the names of visitors and welcome messages, which presents the company as professional, modern, and hospitable. The first impression is significantly improved; new employees feel accepted more quickly, visitors appreciate the attention and organization, which positively affects reputation and company culture.

Because the client’s policy did not allow use of mobile devices on the shop floor, maintenance staff did not have access to the ccLEAP app for tracking and reporting production downtime. Therefore, we developed a digital display that shows production stoppages and breakdowns in real time to maintenance staff. This solution enabled faster response, reduced downtime, and improved maintenance team efficiency — without the need for personal mobile devices.

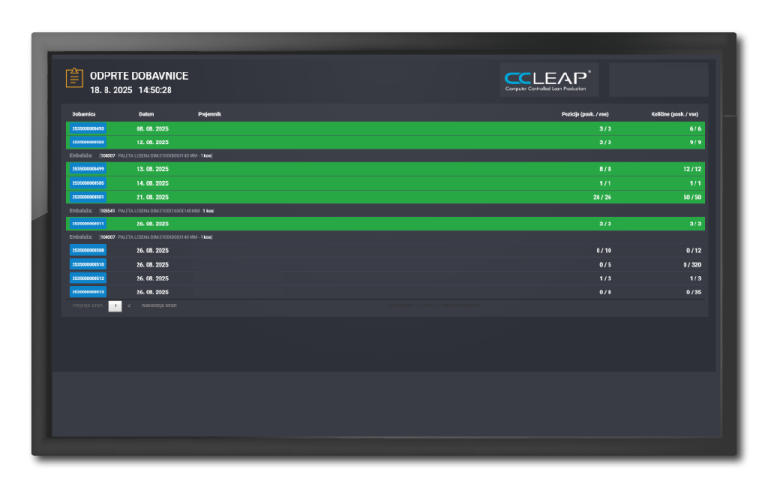

A display in production shows open delivery notes and orders in real-time. Employees and management immediately see what is still open, which tasks are priority, and where bottlenecks are occurring. Clear status labels and automatic refresh ensure transparency, faster decision-making, and fewer errors.

Smart Manufacturing:

benefits of digital displays

Ensure better control, greater efficiency, and improved communication between employees and management.

Informing employees

Based on collected information about energy consumption by individual machines, lines, or the whole facility, you can make informed decisions to reduce costs, optimize processes, and increase energy efficiency.

Boost in productivity

Reliable data on energy consumption enables smart and strategic decisions that lead to greater efficiency and lower costs.

Discover Where Your Energy Really Goes

Understand whether energy is being wasted by downtime, idling, or inefficient processes, or whether it is being used for productive work and creating added value.

Education

Encourage behavioral change among employees to reduce energy waste, and support a culture of continuous improvement in manufacturing by involving employees, monitoring key indicators, and fostering responsible use of energy at all levels.

Instant Flow of Information

Displays are often used in production to improve process transparency and reduce errors, since they allow direct transmission of key information.

Easy Installation. Immediate Data Display.

A simple plug-in solution for monitoring energy consumption — quickly deployed, without complex interventions and with minimal impact on production.

Ready to learn more?

Find out how ccLEAP’s content display functionality can help with employee notifications and production monitoring.