ccLEAP Energy consumption monitoring

Overview and analysis of energy consumption

ccLEAP provides a comprehensive overview of energy usage and enables data-driven decision-making to effectively reduce energy usage.

Why monitor electricity consumption?

Machine-level, product-level, and period-based tracking – in real-time or via historical analysis.

Identify which machines consume excessive energy and take action.

Understanding where and how energy is used helps lower costs, carbon footprint, and promote more sustainable production.

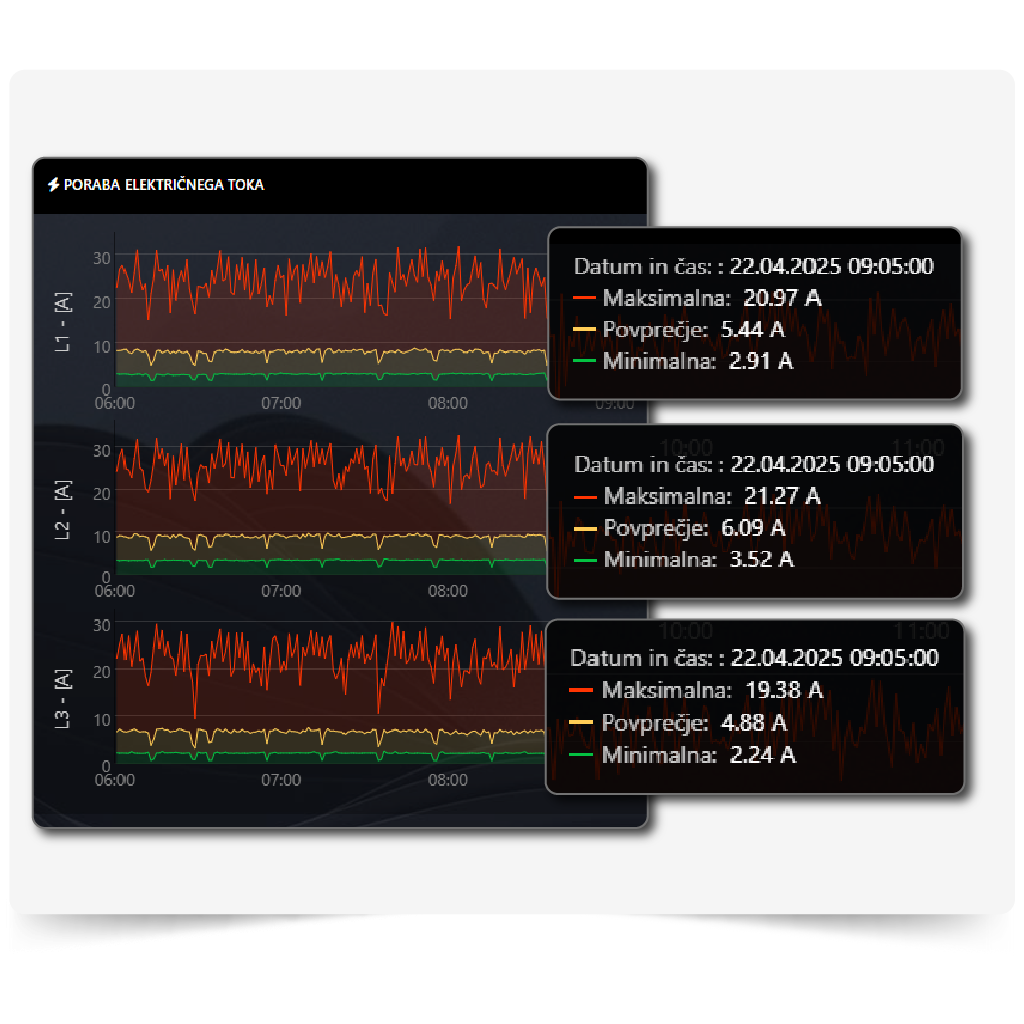

Electricity consumption

by machine

Energy consumption by individual machines often represents a significant part of costs. Accurate monitoring is crucial for cost optimization and improving competitiveness.

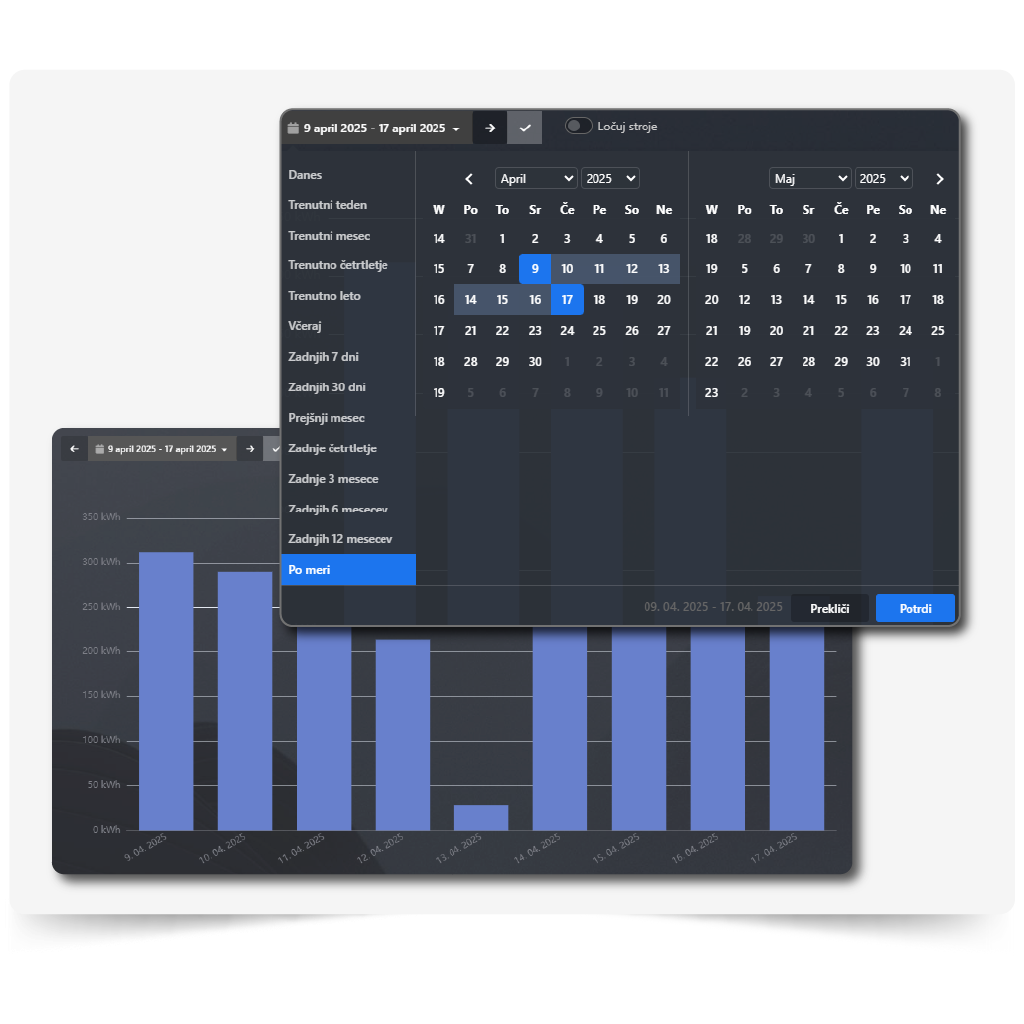

Time-based overview of energy consumption

The ccLEAP Portal offers advanced tools to track performance by asset, line, department, or location – with insights into current operating conditions and historical OEE (Overall Equipment Effectiveness). These insights enable faster decisions, reduced losses, and optimization of key process points.

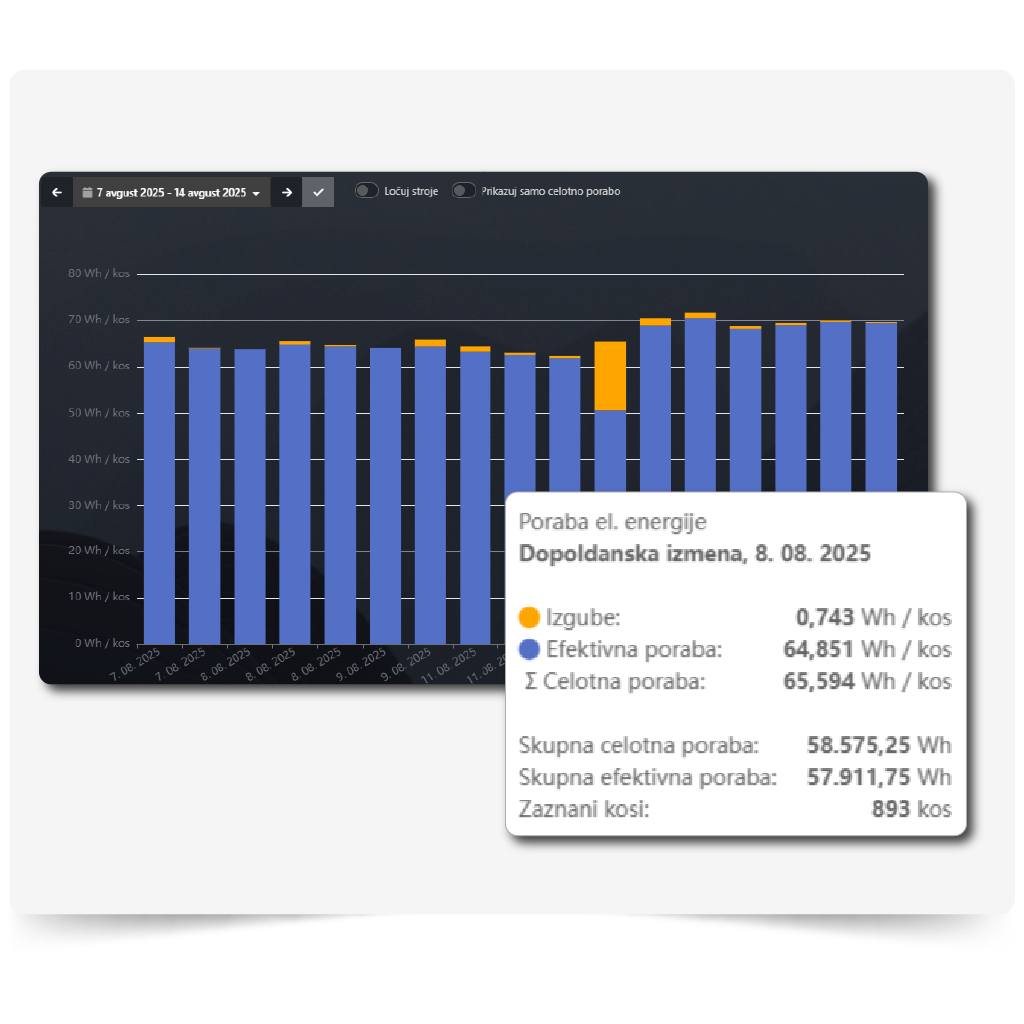

Electricity consumption

per piece

Reduce production costs by accurately monitoring and understanding energy consumption per unit, thereby improving efficiency and optimizing resource utilization.

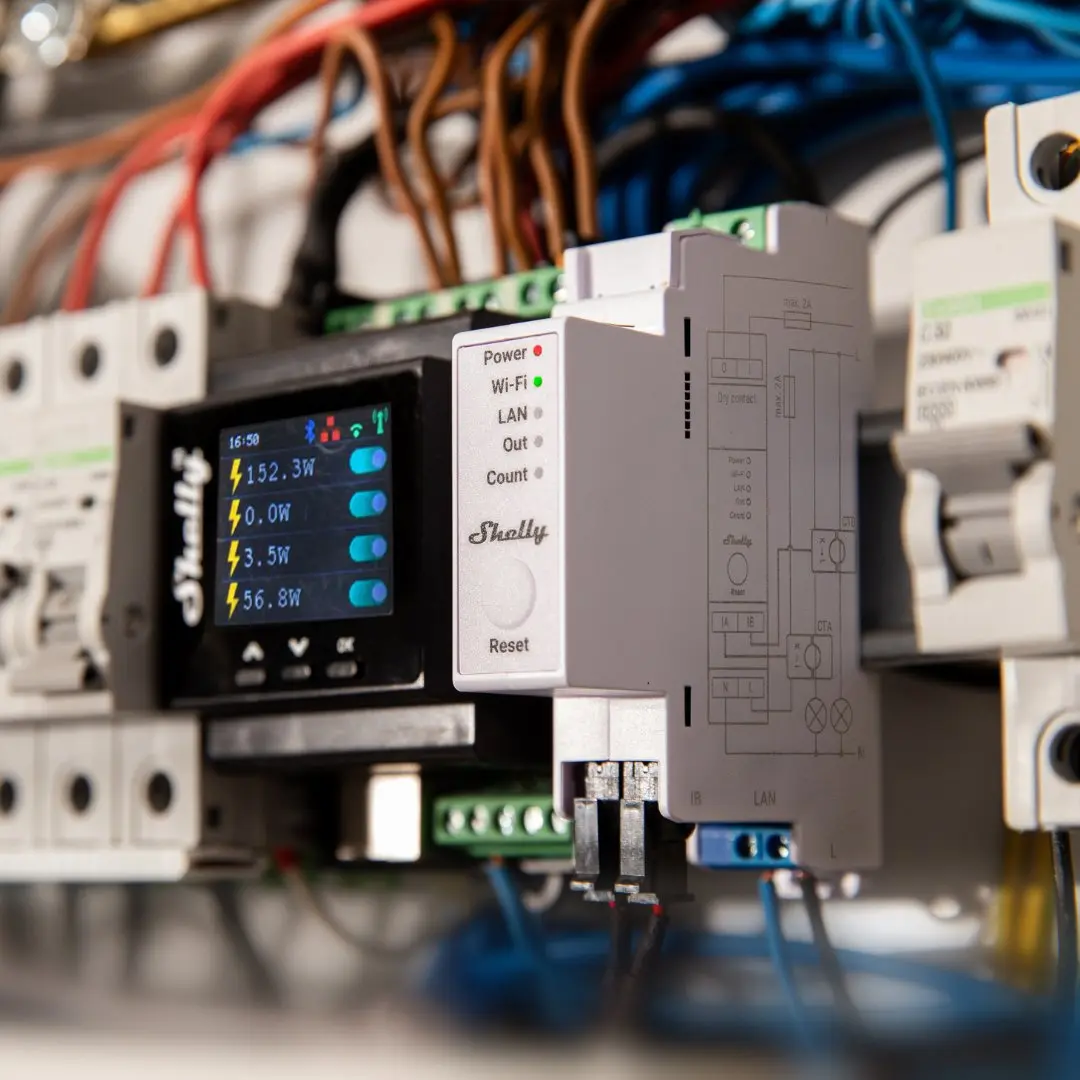

Complete automation

of energy consumption control

Smart metering systems for real-time monitoring, supported by advanced sensors and digital tools, quickly detect deviations and inefficiencies. ccLEAP supports various metering techniques, allowing adaptation to different equipment, energy sources, and processes.

Advantages of

energy consumption monitoring

Monitoring energy consumption helps reduce costs, improve efficiency, and support sustainable operations. Gain insights that enable smarter decisions and continuous improvement.

Based on the information obtained about the electricity consumption of individual machines, lines, or entire plants, you can make informed decisions to reduce costs and optimize production.

Reliable energy consumption data enables smart and strategic decisions that lead to greater efficiency and lower costs.

Find out whether energy is being wasted due to outages, downtime, or inefficient processes, or whether it is actually being used for productive work and creating added value.

Encourage behavioural change among employees to reduce energy waste and support a culture of continuous improvement in production by involving employees.

Gain detailed insight into the carbon footprint of individual machines and strengthen your initiatives for sustainable and energy-efficient production.

A simple plug-and-play solution for monitoring energy consumption – quick to install, no complicated procedures, and minimal impact on production operations.

Are you ready to learn more?

Discover how ccLEAP's energy monitoring functionality can help you turn machine data into concrete productivity improvements.