Monitor, analyze and improve

Machine monitoring software

ccLEAP is a powerful system for monitoring key production performance indicators, providing complete insight into the actual efficiency of your manufacturing processes.

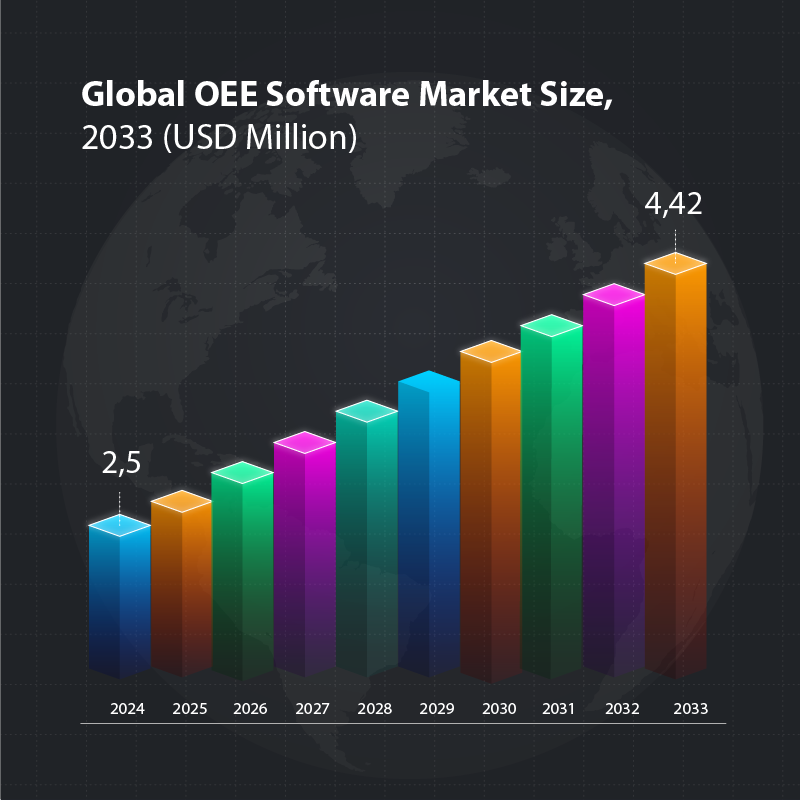

Why monitor OEE indicators?

19 %

Implementing OEE functionality in the manufacturing environment contributes to an approximate19% productivity boost.

14 %

(2023 - 2024)

European users reported, on average, 14% fewer unplanned stoppages.

1.900

1.900+ OEE systems were implemented across Europe in 2024, representing around 28% of the global share.

What is OEE

and why is it critical for modern manufacturing?

OEE (Overall Equipment Effectiveness) is a straightforward metric measuring how effectively a production machine or line operates. It accounts for actual working time, operational speed relative to the potential speed, and the output of defect-free products. The higher the OEE score, the more efficient the production.

OEE - indicator for production optimization

ccLEAP’s OEE monitoring software provides a comprehensive view of production efficiency. By using our controllers and sensors connected directly to machines, you can swiftly detect losses, bottlenecks, and opportunities for improvement.

Real-Time

monitoring dashboard

Get access to real-time data from anywhere at any time. This enables staff to quickly spot deviations and respond in a timely manner—significantly improving responsiveness and streamlining production processes.

Identify losses, optimize processes

Use ccLEAP’s analytical tools to track OEE trends and compare performance over time. This empowers you to identify improvement opportunities and boost manufacturing efficiency.

Automated capture of

OEE indicators

Through reliable industrial hardware and support for a wide range of standards and protocols, the ccLEAP system enables direct data capture from machinery, delivering immediate access to information essential for informed decisions and optimized production.

Steps to successful integration into the production environment

A concise overview of the key steps for successfully integrating ccLEAP Machine Monitoring into your production environment:

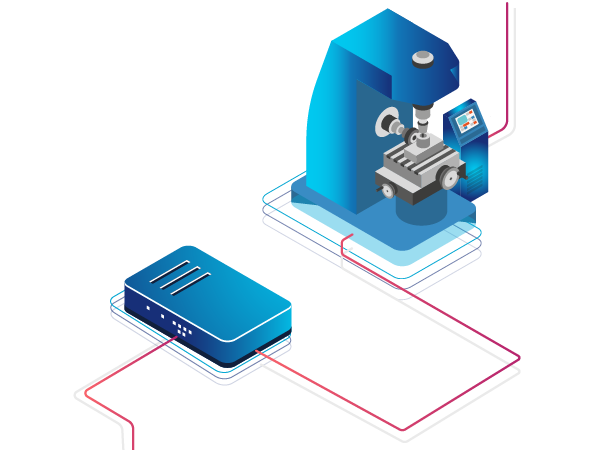

1. Machine connection

Quickly integrate all machines with the ccLEAP system. Modern machines connect directly, while older ones can be outfitted with custom sensors to enable real-time parameter monitoring.

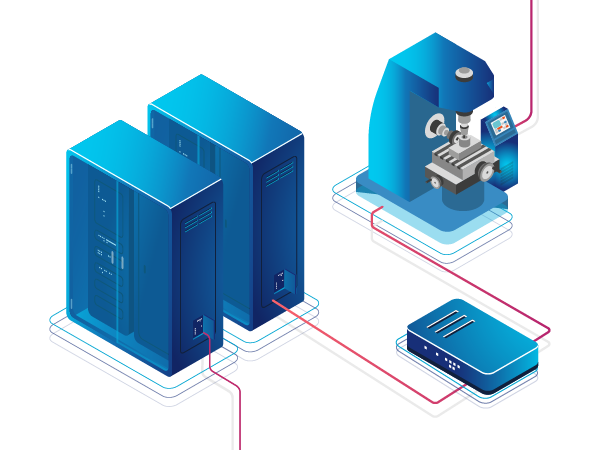

2. Data capture and collection

Once integrated, the system continuously captures and collects data, providing a comprehensive real-time view of machine efficiency, condition, and utilization.

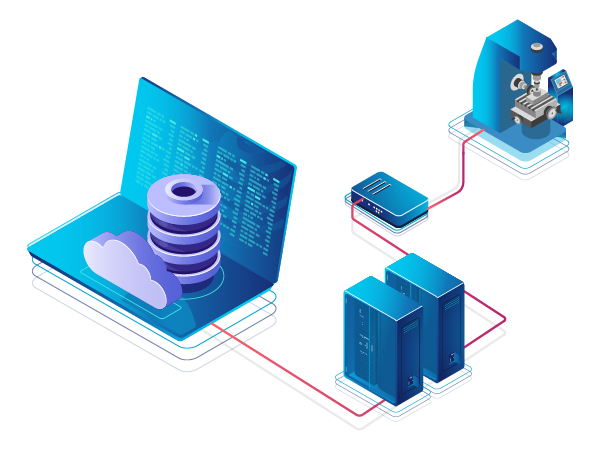

3. Data analysis and visualization

Analyzing and displaying this data supports better decision-making, reduces unplanned downtime, and boosts overall production efficiency—laying the foundation for the smart factory of tomorrow.

They trust us:

Frequently Asked Questions

-

Does my machine support data capture?

Most modern machines support connectivity via standards such as OPC UA, Modbus, Ethernet/IP, or include built-in PLCs with digital outputs. Older machines can be retrofitted with additional controllers and sensors as needed. Alternatively, operation detection can even be based on power consumption.

-

How is the ccLEAP System installed?

- Hardware: sensor installation, connection to controllers or communication hubs

- Software: system configuration, KPI setup, integration with production systems (MES, ERP)

- Often takes place in several phases (pilot implementation, testing, expansion) -

Who has access to the data and how is it protected?

Access is regulated by user rights. Data can be stored locally or in the cloud, with encryption and security protocols (e.g., VPN, HTTPS). The system allows for multi-level access—operators, maintenance staff, management, etc.

-

What happens if there is a system failure?

It depends on the type of failure. Our controllers also record data locally in the event of a failure. Data is also recorded locally on concentrators that we set up for larger systems. When operation is restored, the data is transferred to data warehouses.

-

What training is required to work with the ccLEAP system?

Our solutions are designed to be as simple and user-friendly as possible. In addition, we also offer basic training for users—operators, maintenance personnel, and management—as well as ongoing support in using the system.

Or you can simply drop by for a coffee – we will be happy to discuss your challenges and the solutions we offer.