ccLEAP Prikazovalniki

Sodobna rešitev za prikaz podatkov v proizvodnji

Z digitalnimi prikazovalniki učinkovito in zanesljivo posredujete ključne informacije neposredno na delovna mesta.

Pregled, planiranje in komunikacija

Planska tabla omogoča prikaz podatkov v realnem času, kar zagotavlja takojšen vpogled v stanje proizvodnje in lažje sprejemanje odločitev.

Povečajte informiranost zaposlenih z jasnimi vizualnimi opozorili in sporočili, ki zagotavljajo usklajenost celotne ekipe.

Hiter in pregleden pretok informacij v proizvodnji za izboljšanje usklajenost med ekipami in takojšen odziv.

Enostaven način deljenja vsebine

ccLEAP prikazovalniki vsebin so preprosti za uporabo in visoko prilagodljivi. Poleg standardnih grafičnih prikazov omogočajo tudi razvoj popolnoma prilagojenih (custom-made) rešitev po meri naročnika.

Tako lahko vsebino prikažete točno tako, kot jo potrebuje vaš proizvodni ali poslovni proces.

Izbirajte med različnimi ccLEAP Prikazovalniki

Širok nabor prikazovalnikov vam omogoča prilagajanje vsebine različnim lokacijam in potrebam zaposlenih.

A company sought to increase transparency and employee involvement in the production process, so they introduced digital displays that show key production metrics like OEE, plus other important operational data in real time. Previously these data were accessible only to management or arrived with delay; now they are visible to all employees in prominent locations on the production floor. This allows employees immediate insight into results, downtimes, and potential issues, encouraging greater accountability, faster action, and stronger motivation to reach production goals and continuous improvement.

To improve internal communication, a company installed digital displays in visible places in production where staff can monitor important announcements, changes in the work process, weather forecasts, clock, and other useful information in real time. Previously, information was often communicated with delay or verbally, causing confusion and mistakes. With the installation of displays, the flow of information has significantly improved; employees are always up to date, contributing to better team alignment, timeliness, awareness, and satisfaction.

At the customer’s production facility, workers used to spend up to 45 minutes every morning manually assigning operators to machines, which delayed production startup. Introducing a digital planning board, which enables automatic and clear scheduling based on staff availability and order status, reduced this process to less than 10 minutes. Workers now immediately see where to start at the beginning of their shift, enabling a faster start, greater efficiency, and better utilization of working time.

Digital displays for safety announcements, alarms, and reminders about mandatory use of personal protective equipment significantly improve the flow of key information in the workplace. Previously, employees were often informed with delay or via paper notices which were not always visible or up to date. Now important alerts are automatically shown in real time, directly where they are most needed. This increases awareness of safety measures, reduces the risk of workplace accidents, and strengthens the safety culture among employees.

By installing a digital board at the company entrance, company XYZ enabled a warm and personalized welcome for visitors, new employees, and business partners upon arrival. Previously such greetings were rare or prepared manually; now the board automatically displays the names of visitors and welcome messages, which presents the company as professional, modern, and hospitable. The first impression is significantly improved; new employees feel accepted more quickly, visitors appreciate the attention and organization, which positively affects reputation and company culture.

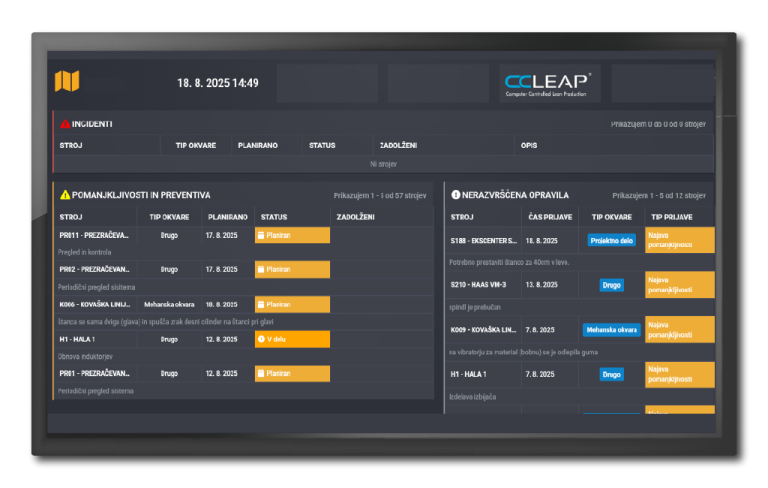

Because the client’s policy did not allow use of mobile devices on the shop floor, maintenance staff did not have access to the ccLEAP app for tracking and reporting production downtime. Therefore, we developed a digital display that shows production stoppages and breakdowns in real time to maintenance staff. This solution enabled faster response, reduced downtime, and improved maintenance team efficiency — without the need for personal mobile devices.

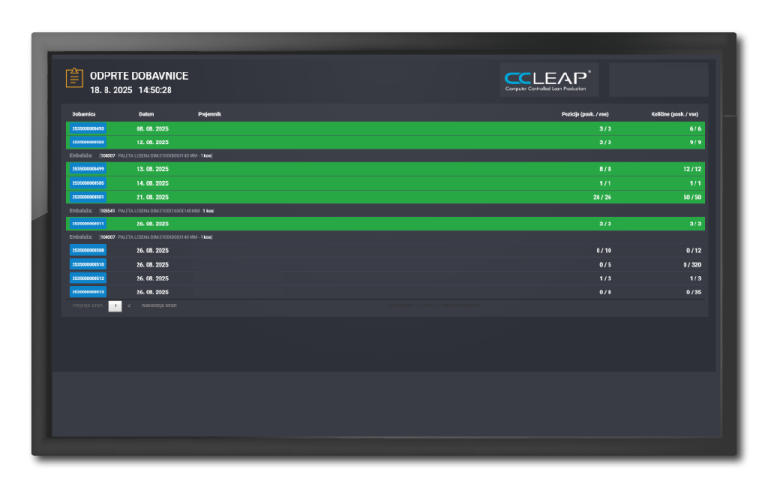

A display in production shows open delivery notes and orders in real-time. Employees and management immediately see what is still open, which tasks are priority, and where bottlenecks are occurring. Clear status labels and automatic refresh ensure transparency, faster decision-making, and fewer errors.

Pametna proizvodnja:

Prednosti digitalnih prikazovalnikov

Zagotovite boljši nadzor, večjo učinkovitost in boljšo komunikacijo med zaposlenimi in vodstvom.

Obveščanje zaposlenih

Na podlagi pridobljenih informacij o porabi električne energije, ki jo porabi posamezen stroj, linija ali celoten obrat, lahko sprejmete utemeljene odločitve za zmanjšanje stroškov, optimizacijo proizvodnih procesov in povečanje energetske učinkovitosti.

Povečanje produktivnosti

Zanesljivi podatki o porabi energije omogočajo sprejemanje pametnih in strateških odločitev, ki vodijo k večji učinkovitosti in nižjim stroškom.

Varnost na delovnem mestu

Spoznajte, ali se energija zapravlja zaradi izpadov, mirovanja ali neučinkovitih procesov, ali pa se dejansko porablja za produktivno delo in ustvarjanje dodane vrednosti.

Izobraževanje

Spodbujajte spremembo vedenja zaposlenih za zmanjšanje energetske potratnosti ter podpirajte kulturo stalnih izboljšav v proizvodnji z vključevanjem zaposlenih, spremljanjem ključnih kazalnikov in spodbujanjem odgovorne rabe energije na vseh ravneh proizvodnje.

Takojšen pretok informacij

V proizvodnji so prikazovalniki pogosto uporabljeni za izboljšanje preglednosti procesov in zmanjšanje napak, saj omogočajo neposreden prenos ključnih informacij.

Enostavna namestitev. Takojšen prikaz podatkov.

Enostavna priključna rešitev za spremljanje porabe energije – hitro nameščena, brez zapletenih posegov in z minimalnim vplivom na delo v proizvodnji.

Ste pripravljeni izvedeti več?

Odkrijte, kako vam lahko ccLEAP funkcionalnost za prikaz vsebine pomaga pri obveščanju zaposlenih in nadzoru v proizvodnji.